Programmable Logic Controllers - PLC (Part -3)

PLC Addressing and Basic Instructions

Basic addressing

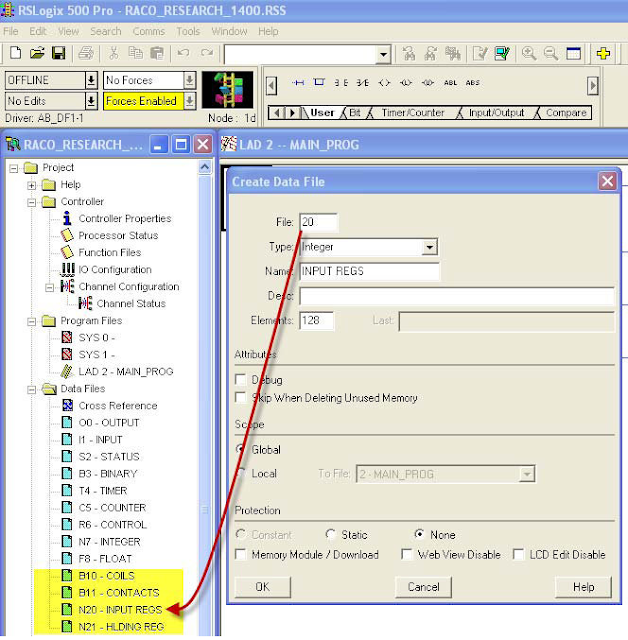

• For the Allen-Bradley PLCs and the

simulator used, the input and output image areas (in addition to other data)

are held in “data files”

• Each “data file” holds information

such as

Discrete input values

Discrete output values

Values associated with timers

Values associated with counters

Status information

PLC data files

I/O memory mapping

Example Addressing

Basic instructions

•

Examine If Closed (XIC)

•

Examine If Open (XIO)

•

Output Energize (OTE)

•

Output Latch (OTL)

•

Output Unlatch (OTU)

•

One-shot Rising (OSR)

Examine if closed (XIC)

• Alternate name: Normally open

contact

• Use the XIC instruction in your

ladder program to determine if a bit is on. When the instruction is executed,

if the bit addressed is on (1), then the instruction is evaluated as TRUE.

When the instruction is executed, if

the bit addressed is off (0), then the instruction is evaluated as FALSE.

Examine if open (XIO)

• Alternate name: Normally closed

contact

• Use the XIO instruction in your

ladder program to determine if a bit is off. When the instruction is executed,

if the bit addressed is on (1), then the instruction is evaluated as FALSE.

When the instruction is executed, if

the bit addressed is off (0), then the instruction is evaluated as TRUE.

Output energize (OTE)

• Alternate name: coil

• This instruction is usually used in

conjunction with XIC or XIO or any other input instruction.

• If the logic preceding the OTE

instruction is true (1), the OTE instruction will be energized

Output latch (OTL)

• The OTL instruction is used only

to turn

a bit on and latch it on

Output unlatch (OTU)

• The OTU instruction is used only

to turn a bit off and latch it off

• OTL and OTU are generally used

in pairs

One-shot rising (OSR)

• When the rung conditions preceding

the OSR go from false to-true, the OSR instruction goes

true also but for only one scan

Branches

• Branches can be inserted in ladder logic programs to

create parallel combinations of various ladder logic elements

Multiple Series/Parallel Branches

• Multiple series/parallel branches

can be utilized with multiple inputs and also affecting multiple outputs in parallel

PLC simulator usage

• Ladder logic elements

(instructions) can be dragged and dropped onto the ladder window to create a ladder

logic program

• The ladder logic program is

executed by going online, ‘downloading’ the PLC program, and switching to run

mode

ProSim simulations

• The Logixpro simulator provides a

set of built-in simulations

• The I/O simulation initially will

be of most use since it provides access to simulated discrete inputs (switches)

and outputs (lamps)

Other Prosim simulations

•

Available simulators

Door

simulator

Silo

simulator

Traffic

simulator

Batch

simulator

Dual

Compressor simulator

Bottle

line simulator

Multi floor elevator simulator

• Most projects will involve designing ladder logic programs to control these simulations

1.Door

simulator

2. Silo

simulator

3. Traffic

simulator

4. Batch

simulator

5. Dual

Compressor simulator

6. Bottle

line simulator

7. Multi floor elevator simulator

THANK YOU

Popular

Popular Tags

Tags Videos

Videos

0 comments:

Post a Comment